This Humanoid Robot Might Build Your Next BMW

Honda (Asimo) and Tesla (Optimus) aren’t the only automakers to experiment with humanoid robots. BMW also has a few of its own and is currently exploring using them in production for the first time.

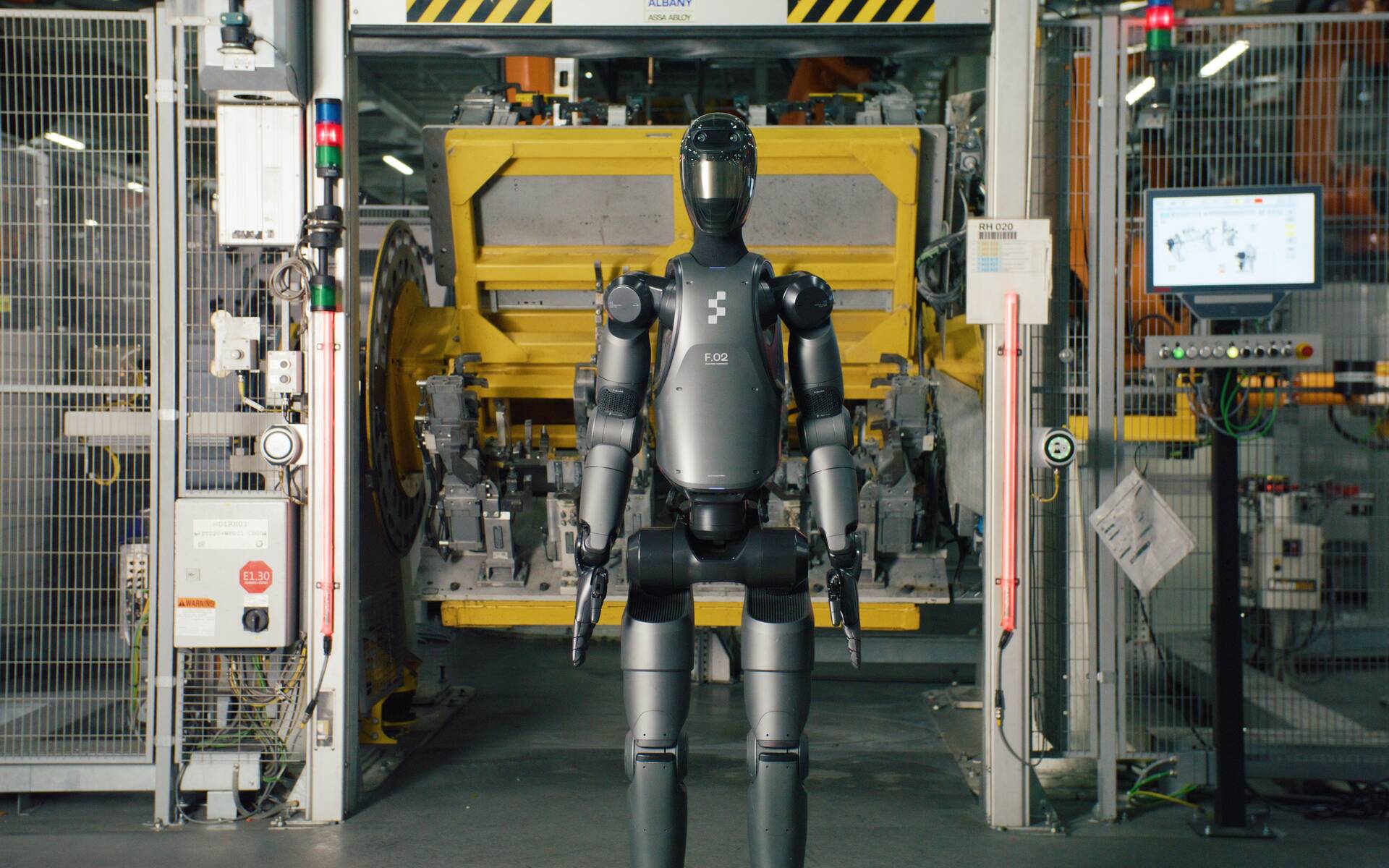

The German manufacturer turned to California company Figure, whose latest-generation model is the Figure 02 you see here.

- Also: BMW X5 Turns 25 in Canada, Celebrates With Special Edition

- Also: Next-Gen BMW iDrive Unveiled With Panoramic Vision

During a trial run lasting several weeks at the Spartanburg plant in South Carolina, Figure 02 units successfully inserted sheet metal parts into specific fixtures, which were then assembled as part of the chassis. Such manipulations require particular dexterity, as BMW points out.

The main goal with using these robots is to save employees from having to perform ergonomically awkward and tiring tasks.

“The developments in the field of robotics are very promising. With an early test operation, we are now determining possible applications for humanoid robots in production. We want to accompany this technology from development to industrialization,” says Milan Nedeljković, Member of the Board of Management for Production at BMW AG.

The automaker said the trial run gave it valuable knowledge of what requirements must be met in order to be able to integrate multi-purpose robots in an existing production system. This includes how humanoid robots communicate with the system under real conditions, what their productivity and limitations are, and how safely and conveniently they can work with human workers in various work stations.

According to the California company, Figure 02 is the world’s most advanced humanoid robot currently available on the market. It boasts three times the processing power of its predecessor, improved voice communication, better cameras, microphones and sensors, a high-performance battery, as well as human-scale hands with 16 degrees of freedom per hand and human-equivalent strength.

Not only that, but the robot is capable of fully autonomous execution of human-like and two-handed tasks requiring varied and dynamic manipulation, such as placing various complex parts with accuracy measured in millimetres.

BMW says there is no definite timetable established for bringing humanoid robots to the Spartanburg plant, which currently assembles the BMW X3, X4, X5, X6, X7 and XM. We can’t help but wonder what the UAW union has to say about that, though. Sparing employees from tiring tasks is one thing, but potentially cutting jobs is another.